Brought to you by: DirectPneumatics.com

Always ask if we can get products to test!

Questions to ask:

- Is the product porous or non-porous?

- Can we get a picture of the product we are lifting? This is mainly to see the shape and area we need to pick from. If not, we need a detailed description but that makes it harder.

- What are the dimensions of the object and how much do they weigh?

- Do we need to pick up more than one product at a time? If YES, see below for follow up questions:

- Are we picking all products at once and then placing them, or do we need to have individual control of each part?

- Are the products always in the same exact location? If the product can be +/- 2mm in any direction, this could make the entire array have huge variations and we must consider that variable in the design of the solution. (less common of an issue in box palletizing and depalletizing applications)

- What are the array layouts for each product?

- Are there any parameters for the multi-pick, ex. Vac Gripper needs to fit in a box to place so the gripper can only be so big. Reason; because of the space where it will be mounted since the gripper can only weigh so much because of the robot payload and product weight. (these questions can apply to a one product pick as well)

- Do they already have a vacuum source? Is compressed air possible? Larger grippers, porous products, cups open to atmosphere during the pick or a larger qty of venturis in the same plant might make a venturi debatable due to air consumption or lack of the flow needed. We may need to go to an electric pump: Rotary Vane, Regen blower or Claw depending on flow requirements for the pick.

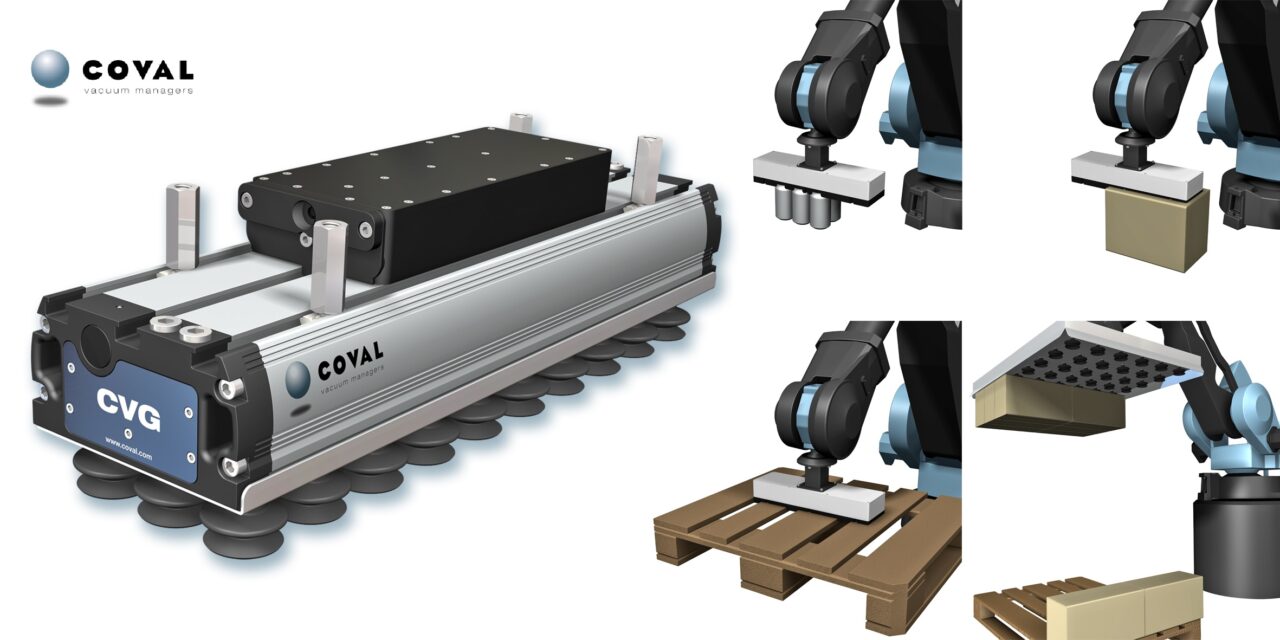

- More than one identical gripper, i.e. Coval’s CVGL and MVG, purchased at the same time may create cost savings but only if the grippers are identical. Ask if they need more than one.

- What is the cycle time?

- Can you describe the application movement? Is the product ever held in sheer?

- Are there any other parameters we should consider? Ex. FDA Compliance, dirt, grit, moisture or debris, wash down, temperature etc.

- Is this a Budgetary or does the customer need a finalized quote? How quickly do they need the quote by?

Sometimes you are looking at an application where the end customer is looking to upgrade a current tool or correct an issue they are having with a current tool. If this is the case, ask what exactly the issue they’ve been seeing is. This might be helpful for us in the design to make sure we don’t follow that mistake.

This is a great place to start with customers when trying to qualify an application. Some of these questions may not apply depending on answers to previous questions. An application where a few cups are needed probably won’t warrant a gripper (CVGL, MVG, CVGC) so some of the questions geared more towards a gripper, may not apply.