This article about end-Position Cushioning was written by Fabco-Air, a partner of Direct Pneumatics.

![]()

Although end-position cushioning is a well-known and necessary feature of many pneumatic cylinders, it can be easy to overlook certain aspects of cushioning and unintentionally diminish your system’s overall performance or reliability. For example, little or no cushioning can cause a load to strike the end cap with too much force, causing shock loads and vibrations that can damage both your cylinder and other parts of your machine. And, too much cushioning can slow down the process and hurt productivity.

This white paper will provide an overview of end-position cushioning concepts and technologies, providing considerations to help select the best cushioning option for your application. It will also offer tips and best practices to help you get the most benefit from your pneumatic actuator.![]()

FULL STOP: END-POSITION CUSHIONING OPTIMIZES PNEUMATIC SYSTEM PERFORMANCE

In order to meet always-increasing throughput demands while saving on costs for automated systems, machine designers often push the performance envelope by decreasing cycle times as much as possible. For pneumatic drives, where the compressed air can cause the piston to reach its peak travel speed at or near the end positions, the impact energy will be high. Without a means to decelerate the fast-travelling load, the resulting impact forces to the end cover can introduce several problems, such as:

• Premature wear to the cylinder and other components.

• Shock and vibration transmission throughout the machine.

• Reduced cylinder accuracy.

• Excessive noise.

• Piston bounce, or rebounding.

Good end-position cushioning dramatically decreases the impact forces at the end of a pneumatic cylinder’s stroke to reduce shock and stress, playing a crucial role in defining the minimum travel time and maximum speed of pneumatic cylinders so you can achieve high productivity, greater efficiency and a long lifetime for your machine. ![]()

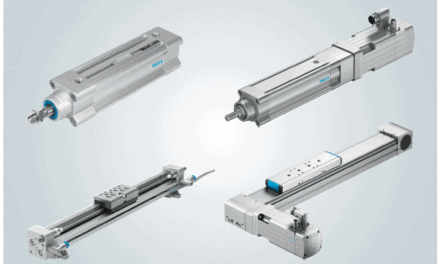

SELECT AN APPROPRIATE CUSHION FOR YOUR CYLINDER

Most pneumatic cylinders come with pre-installed end-of-stroke cushioning. Here’s an overview:

Elastomer cushions. Virtually all cylinders offer elastomer cushions — also known as bumpers — either standard or as an option. These bumpers minimize impact noise and can dissipate small amounts of impact energy, such as from lightweight loads. However, the quality and hardness of elastomer materials can vary among manufacturers. And, for applications with higher kinetic energy, a larger, more durable damping method is necessary to prevent damage.

Adjustable pneumatic cushions. Heavier-duty cylinders, and cylinders with strokes longer than three or four inches, often come equipped with additional cushioning to handle larger loads and dynamic forces. One option is to use a fixed (non-adjustable) pneumatic cushion, whereby the exhaust air is forced through a fixed orifice pathway — similar in appearance to a metal washer — to provide the end-position cushioning. These can save setup time and prevent tampering, and are best suited for applications where the loads and speed do not vary. However, the cushioning performance may not be suitable for all situations, and users do not have the ability to adjust or tune the cushioning to achieve optimal performance.

Adjustable pneumatic cushioning, however, lets engineers tune their cushion according to their needs. The cylinder incorporates a cushion seal in the end cap, which traps a small volume of air between the piston and the end position, providing a controlled deceleration of the piston at the end of the stroke. The braking effect is determined by a needle valve that exhausts trapped air near the end cap. Users can adjust the valve with an adjusting screw, taking into account the moving mass, operating pressure and the piston speed. Note that readjustments may be required after a certain number of cycles in order to maintain optimal long-term cushioning performance.

Cylinders with adjustable end-position cushioning dissipate all the kinetic energy at the end of the stroke, so braking time is faster, shock and vibration are eliminated and wear is reduced. The result: shorter cycle times, greater productivity and longer lifetime for the cylinder.

Adjustable pneumatic cushions are built into many Fabco-Air cylinders — depending on the size — such as our F Series round body, ISO 6431-compliant FAQ2R and ISO 6432-compliant FAE Series, as well as our NFPA and OEM-NFPA cylinders which offer the convenience and versatility of NFPA interchangeability. With some of our NFPA cylinders, optional adjustable air cushions may be used together with silent seal bumpers to further reduce noise.

GET IN TUNE WITH YOUR SYSTEM

Although cushioning is a common concept in pneumatic systems, it’s also easy to lose sight of some rules of thumb that can otherwise prevent you from getting the best performance from your cylinder. Whenever possible, be sure your adjustable end-position cushioning systems are tuned by experienced personnel with knowledge of the intended application. Here are some additional cushioning tips and best practices to follow when implementing pneumatic cylinders into your system:

Know your application requirements. Each application comes with its own dynamics that will affect your cushion’s ability to dampen the impact forces. When it comes to end-position cushioning, there is no one-size-fits-all solution.

Give your cylinder the right amount of cushioning. If the system does not have enough back-pressure to absorb the kinetic energy, damaging impacts can occur along with the associated wear, shock and noise that can lead to problems. Conversely, too much damping will slow the load prematurely, causing the load to bounce during braking as the piston changes direction. This can slow down your cycle times and transmit damaging vibrations into the system.

Communicate with your installer. In an effort to get up and running quickly, machine builders and installers may inadvertently bolt the cylinder into the system without realizing it has a built-in cushion. Without properly tuning the cushion to the dynamics of the application, the cylinder may underperform.

System settings affect cylinder performance. Conditions throughout the system can affect the dynamics within the cylinder itself, so be sure to retune the cushion whenever you make changes to the system such as its operating pressure, load and speed.

DETERMINE THE BEST END CUSHION WITH YOUR CYLINDER MANUFACTURER

End-position cushioning is an often overlooked aspect of pneumatic system design. However, with careful consideration of your damping options with respect to your load weight, travel speed, cylinder size and weight, stroke length and other factors, you can improve cycle times, efficiency and cylinder lifetime while maximizing your system’s uptime.

Your pneumatic component specialist can help determine the best cylinder and damping combination for your application. Fabco-Air, for example, offers a wide range of quality, durable cylinders including families with NFPA standard dimensions and adjustable air cushioning. Our technical experts have extensive experience working with customers on application details, and they can suggest standard products or tailor a “special” to help solve application-specific challenges.

For more information about end cushioning for your pneumatic cylinders, visit www.directpneumatics.com.