Written by: Direct Pneumatics

Pipe Threads for pneumatics & low-pressure hydraulics

Pipe thread identification is an issue throughout all industrial sectors, both globally as well as domestic. This article will assist with identifying as well as specifying new or replacing components for designs in pneumatic and hydraulic circuits. In this article, we reference a road-map to assist with the understanding and to clear up what exactly these thread acronyms mean.

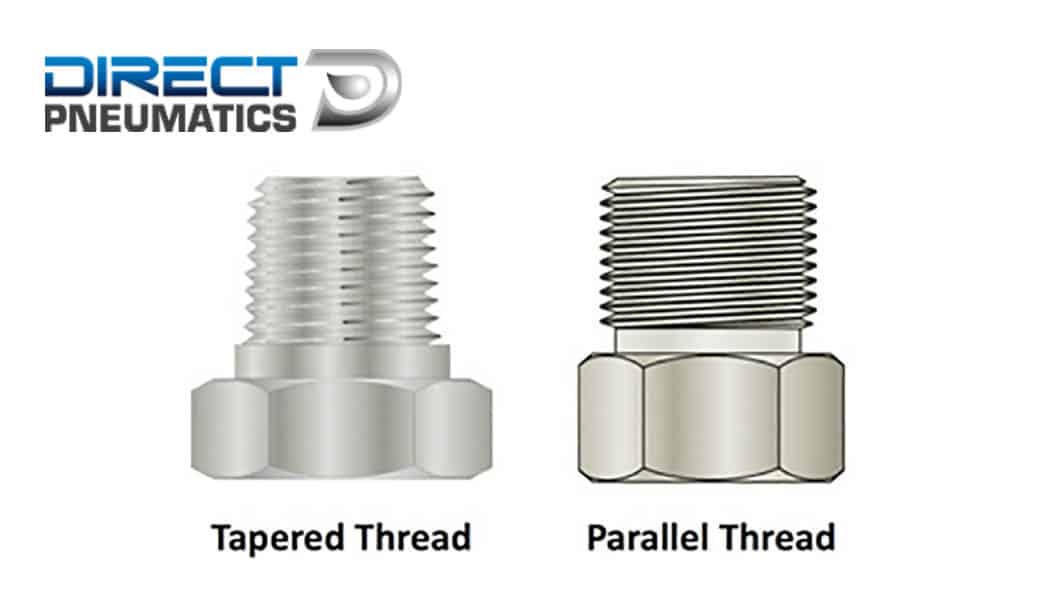

The three types of pipe threads that we’ll focus on are tapered and straight (parallel), BSPP, BSPT, and NPT, which will be discussed further. Parallel type threads will accommodate a sealing ring for leaking purposes, which provide the best seal between the two types. Tapered on the other hand will require either a pipe sealant or by taping the threads. Manufacturers of fittings are now incorporating a sealing material.

- NPT is a National Pipe thread, male MNPT, female FNPT

- BSPP is a British Standard Pipe Parallel, referred as “G” thread

- BSPT is a British Standard Pipe Tapered, referred as “R” thread

These thread standards are common with quick disconnect, barb fittings, brass couplings as well as bite compression type fittings.

Tapered threads

The two tapered styles either BSPT or NPT, mated together are not compatible, and to make matters worse are very difficult to identify. Although there are thread gauges available, the best bet to identify threads would be to access a thread gauge, calipers or another fitting mate.

Attempting to install an MNPT into a BSPP female is not recommended or vice versa, although with larger sizes (e.g. 3/8 thread and larger), the thread pitches are similar. Another important note to make; threading a straight thread BSPP (male G) into a tapered BSPT (female R) is not recommended. Review illustrations below:

For the last 100 years, the most widely used pipe threads in North America were NPT, but with the influx of European and Asian equipment, US, as well as global fitting manufacturers, are adapting to the high demands for the British Standard type fittings, “R” and “G”. Although NPT and BSPT look similar, the thread angle is 60° for NPT threads; 55° for BSPT/BSPP threads. NPT threads are flattened at the peaks and valleys, while BSPT/BSPP threads are rounded.

Some confusion may result in the form of NPT, FNPT, and MNPT in describing threads. Both FNPT and MNPT are NPT threads, with FNPT meaning female threads (internal) and MNPT meaning male threads (external).

Straight threads

Straight (parallel) thread fittings are a great sealing mechanism, which utilizes an O-ring (elastomer), known as BSPP or “G” thread. This O-ring material is inserted between the shoulder of a male thread sealing against the face of a female fitting by squeezing in place, making a tight seal. The picture below shows an adapter with a male BSPP “G” type thread. Notice the O-ring located on the shoulder of the thread.

Summary

Identifying pipe and fitting threads can be difficult at times, but here are a few ideas to consider. If using a quick disconnect pneumatic fittings, measure the OD of the tubing. For example, if the OD measures @ .250”, your tubing most likely is an inch type, so this signifies that your thread size is either NPT or a UNF thread, e.g. 10-32. Measuring the tube @ .235” and the tube is a 6mm OD, so the thread should be either BSPP or BSPT. Another test could be using a go/no-go type gauge, which is the most effective method, or even another mate fittings.

Using a caliper can also be used to take measurements of thread diameters as well. The chart below displays the actual OD of the threads as well as tightening examples. Remember that tapered threads need a sealant or pipe tape for leak-proof sealing.

For a wide selection of pneumatic pipe fittings by brand be sure to visit the Direct Pneumatics site by clicking here