This article is from FESTO, a partner of DIRECTPNEUMATICS.COM.

From electronics manufacturing to automotive assembly, pneumatic mechanical grippers have become an important part of material handling processes in many industries. Their recent growth is tied to the rise of robotics, including the need for robots to take on special tasks and handle increasingly complex workpieces. The result is you now have more grippers to choose from than ever. In North America alone, the gripper market is worth roughly $100 million—and that number is expected to climb up to 5 percent each year.

With all the recent developments in robotics and gripping technology, it can be difficult to know which gripper is best for your application. This white paper will provide an overview of common gripper types, including mechanical, soft, adaptive, vacuum and magnetic. It will also explore their key design features, as well as the benefits they offer in various applications.

Understand What Your Application Demands

To help you select the right gripper, it’s important to first consider the nature of your task, operating environment and workpiece—including its size, mass and material. Some key considerations and questions to ask yourself include:

- Environmental. What temperature range will your gripper operate in? Will your gripper be exposed to dirt, dust, oil or moisture?

- Industry. Does your application involve food or other hygienic workpieces? Will your gripper be exposed to cleaning processes? Does your application require antistatic materials?

- Design constraints. What direction of motion do you need? What is your application’s maximum operating speed? How large is your work space? Will your operators be sharing the space with collaborative robots?

Other factors to keep in mind include upfront, operating and maintenance costs, as well as energy consumption. Grippers fall into several categories, and your answers to the above questions will help you determine which type you need to get the job done as safely and efficiently as possible.

Mechanical Grippers—Proven Reliability, Flexibility and Durability

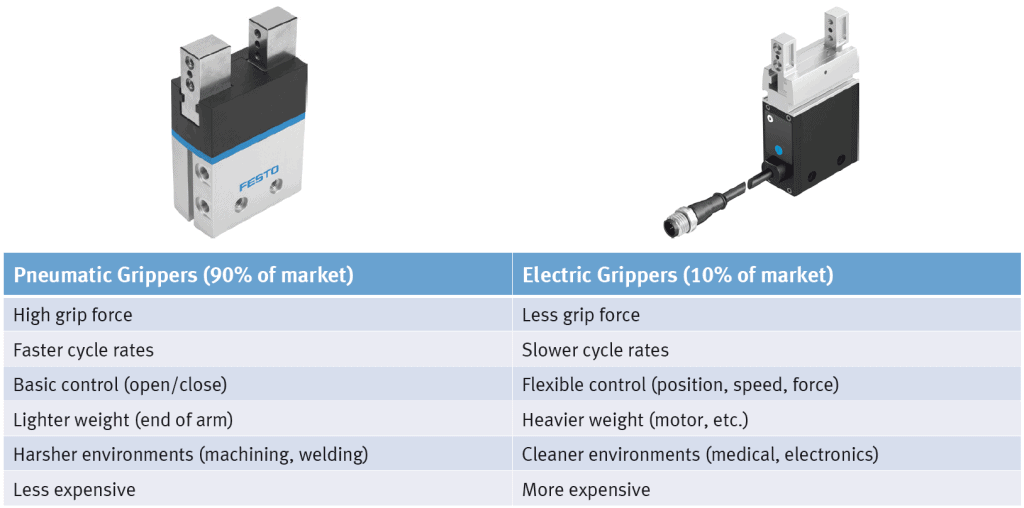

When it comes to handling applications, pneumatic or electric mechanical grippers are the most common. Pneumatic grippers, which make up 90 percent of the market, tend to be more lightweight and cost-effective than their electric counterparts. They also feature higher grip forces, can handle faster cycle rates and are more suitable for harsh environments. Electric grippers, on the other hand, offer greater precision, affording end-users with force and travel control. At the same time, they tend to be heavier due to the presence of a motor and other internal components, which also drives up their upfront costs.

Whether electric or pneumatic, mechanical grippers fall into several design classes. Parallel grippers, for example, incorporate fingers that pull directly apart. Two-finger designs are the most common, making up 85 percent of the mechanical gripper market, while three-finger designs are suitable for handling round objects or performing centering functions. Other examples include radial and angular grippers, which feature fingers that open at an angle. Radial grippers open to 180 degrees, making them suitable for applications involving varying or inconsistent workpiece sizes. Angular grippers tend to be faster than 180 degree designs and open to roughly 30 degrees.

Comparing Pneumatic and Electric Grippers

Comparing the Designs of Three Gripper Fingers

Other important considerations when selecting your mechanical gripper include the gripping force, the guiding strength of the jaws and the design of the gripper itself—all of which depend on the nature of your workpiece. In general, the longer the gripper fingers, the longer the lever arm, which exerts more torque on the jaws. In addition, flat finger designs provide a friction-based grip for bulky or robust parts, while encapsulated designs work best for slippery parts requiring more precision.

We can apply many of these principles to a recent application example, which involved selecting a gripper for a food processing application. The grippers had to pick up large trays with dried pasta, rotate the trays to dump the pasta onto a conveyor belt and then return the trays to their stack. The trays were large, roughly 4 x 2 feet. They were also made of metal and weighed 15 pounds each. Other important considerations included:

Environmental. The grippers would operate at room temperature. The air was dry but contained some dust from the pasta.

• Design constraints. The gripper had to be able to handle high forces, as heavy trays had to be rotated and shaken frequently.

To meet these requirements, we recommended four heavy-duty HGPT mechanical grippers. Thanks to their oval-shaped piston, they provide up to 30-percent more gripping force for heavy objects. They also include sealing air ports, preventing pasta particles from entering the gripper jaw guide. (For more information about our HGPT, see our sidebar.)

Enabling New Automation With Soft and Adaptive Grippers

Enabling New Automation With Soft and Adaptive Grippers

Soft and adaptive grippers can handle workpieces of various shapes, sizes and orientations, enabling automation in areas where it previously didn’t exist. Because they don’t have any sharp edges, these types can handle food, glass and other delicate objects without damaging or marking the surface. They’re also ideal for small work areas. Compared to mechanical variants, however, soft and mechanical grippers are less precise and operate at slower speeds. They are also more susceptible to dirt, oil and other contaminants.

Oftentimes, soft and adaptive grippers incorporate innovative, tweezer-like designs that can adapt to the contours of various workpieces. For example, the Festo DHAS features our Fin Ray® structure, derived from the movement of a fish tail. Two flexible bands, which meet at the top like a triangle, are connected by ribs. Using flex hinges, these ribs are spaced at regular intervals, creating a flexible, yet sturdy joint connection. Available in lengths of 60, 80 and 120 millimeters, this series is ideal for pick-and-place applications involving fragile or irregularly shaped parts. It also incorporates materials that comply with FDA standards, making them a good fit for the food and beverage industry.

Suction Cup Shapes and Surfaces for Vacuum Grippers

Reap the Benefits of Compressed Air With Vacuum Grippers

Another gripper technology is the vacuum gripper, which combines suction cups and vacuum generators. Compact and flexible, these grippers are ideal for limited work spaces and can handle a variety of objects at high speeds. At the same time, however, vacuum grippers can run up your maintenance and operating costs; suction cups are susceptible to quick wear, while generators consume high rates of compressed air and can easily clog in the presence of dust and other contaminants.

Another gripper technology is the vacuum gripper, which combines suction cups and vacuum generators. Compact and flexible, these grippers are ideal for limited work spaces and can handle a variety of objects at high speeds. At the same time, however, vacuum grippers can run up your maintenance and operating costs; suction cups are susceptible to quick wear, while generators consume high rates of compressed air and can easily clog in the presence of dust and other contaminants.

When it comes to suction cups, it’s important to consider the nature of your workpiece when selecting a material. Buna suction cups, for example, are ideal for oily or plain workpieces, while silicon is suitable for food, as well as hot or cold objects. In addition, polyurethane is a good choice for oily, plain and rough workpieces; viton is suitable for oily, plain and hot workpieces; and anti-static buna is ideal for electronics.

Cup shape is also an important factor, especially when it comes to gripping objects that are flat versus round, slim versus large and sturdy versus delicate:

- Standard cups—for flat or slightly undulating surfaces.

- Bellows type—for pliable workpieces, as well as surfaces that are bevelled, domed or round. This type is also suitable for glass bottles, light bulbs and other delicate objects.

- Oval type—for slim or oblong workpieces.

- Extra deep—for round and domed workpieces.

Vacuum sources fall into two categories: electro-mechanical vacuum pumps/blowers, as well as compressed air-driven vacuum generators/ejectors. In general, electromechanical pumps and blowers can achieve high vacuum and suction rates—up to 99.99 percent and 1,200 cubic meters per hour, respectively. At the same time, however, these machines tend to be heavy and large, requiring a reservoir with a complex piping system. Because they run continuously, they also consume a lot of current, which generates heat.

Compressed-air driven generators, especially single-stage units, overcome many of these challenges. Compared to electro-mechanical pumps and blowers, they are more compact, lightweight and easier to install. They include simpler piping systems, require lower upfront costs and incorporate no electrical connections, eliminating harmful heat buildup. Although these units can run up your ai conveying, box making and labeling; and printing applications, such as sheet feeding and handling.

Magnetic Grippers Offer Unique Benefits

Lastly, magnetic grippers from Magswitch® can handle metallic objects like sheets of metal and are ideal for tasks like de-stacking, fixture tooling and bin picking. Although these grippers are limited to applications involving ferrous metals, they require minimal air consumption to actuate, achieving energy savings up to 90-percent compared to suction cup grippers. Other benefits include:

Strong gripping. Magswitch magnetic grippers use a shallow magnetic field that enables material de-stacking.

True ON/OFF. Magnets can be switched completely off and stay clean; any metal fillings left behind from production processes instantly fall away.

Fast. Magswitch magnetic grippers can actuate in 250 milliseconds, saving valuable cycle time.

Safe. They also provide fail-safe performance and will not drop parts in the event of a power or air loss.

Getting Started

No matter your application, there’s an ideal gripper for you. Ultimately, the right choice depends on a number of variables, including workpiece size and shape, operating conditions, industry, energy requirements and cost. In some cases, unique handling applications may even require a custom gripping device.

If that’s the case, our engineering team is here to help.

To learn more, please visit www.festo.com.

Click here to find grippers and accessories