Written by Nexen:

Nexen’s pneumatically-engaged, single-position torque limiters are the highest quality and most efficient overload protection devices for industrial machinery on the market today. They protect your equipment by immediately disengaging the machine shaft when excessive torque or a machine jam occurs. Each unit now comes with a Turck® Proximity Sensor to detect torque overloads. When the sensor detects an overload, it instantly sends a signal to the control valve, exhausting the air and disengaging the Torque Limiter. Releasing the Torque Limiter effectively protects downstream equipment from damage and decreases downtime.

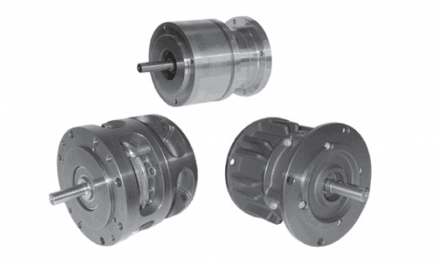

Drive Ring / Drive Flange Assembly

The torque limiter’s hard-chrome detent interface decreases drive-ring deterioration when the balls are pressed against the face during the jog-to-position engagement function. The ball and detent interface prevent facing wear and increase product life. This design also ensures complete disengagement every time, without premature re-engagement, to lengthen product performance with a long life.

Turck Proximity Sensors

The mounting configuration of the Turck Sensor allows full gear reducer shaft insertion into the bore for inline shaft coupling installations. This ensures proper torque transmission and easy mounting. The 24VDC proximity switch is easy to set up and works well with PLC controls.

Sealed Air Chamber

The air chamber is sealed with o-rings and backup rings to prevent air leakages and limit repair costs. The backup rings effectively prevent o-ring dislocation, decreasing wear, and extending the life of the o-ring.

Brought to you by NEXEN, a partner of DIRECTPNEUMATICS.COM