The following is from FESTO, a partner of Direct Pneumatics

FESTO White paper: Pneumatics or electrics – important criteria when choosing technology

The requirements for modern production plants are becoming increasingly complex. It is therefore essential that the drive technology used is the best possible solution for the task at hand. Most linear motions in the field of automation and handling technology are carried out using pneumatic or electric drives. This means that engineers frequently face the challenge of having to find the most appropriate solution for a specific application when planning and designing machines and plants. This white paper describes the important points to bear in mind when it comes to choosing the right technology.

Introduction

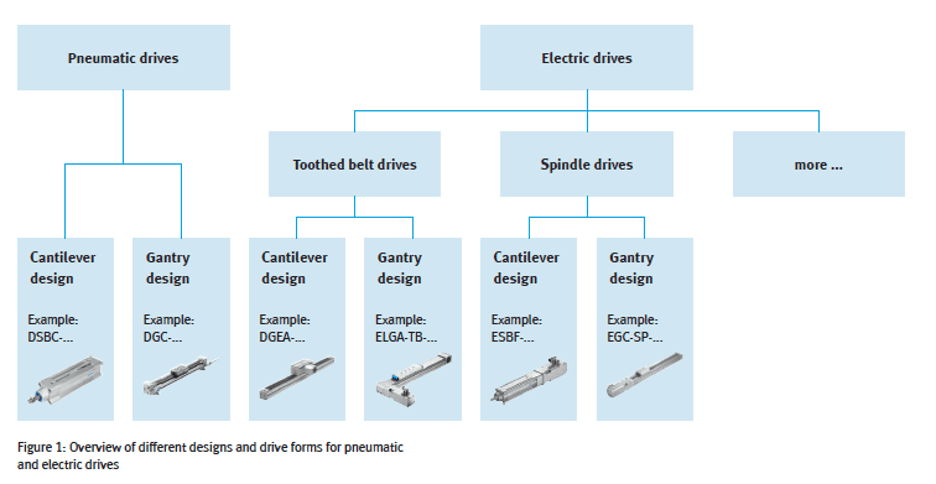

Machine manufacturers generally have a choice of different pneumatic and electromechanical automation solutions when implementing an automation task. However, there is no general advice on when the different technologies are typically used. As a result, the user is frequently faced with the question of which automation technology is best suited, technically and economically, to their individual requirements. In addition, each drive technology also has its own different designs and drive forms that the user needs to consider.

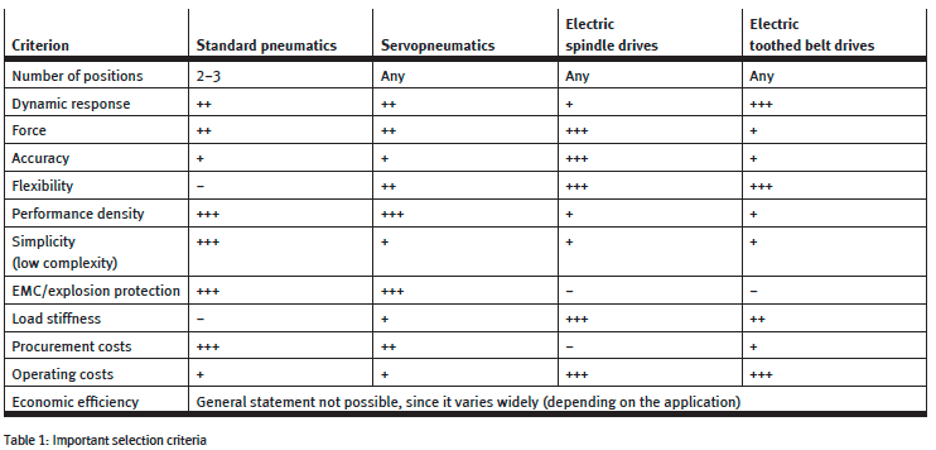

Criteria like dynamic response, force, control characteristics, load stiffness and above all economic efficiency always play an important role when making this decision. These criteria are briefly discussed below.

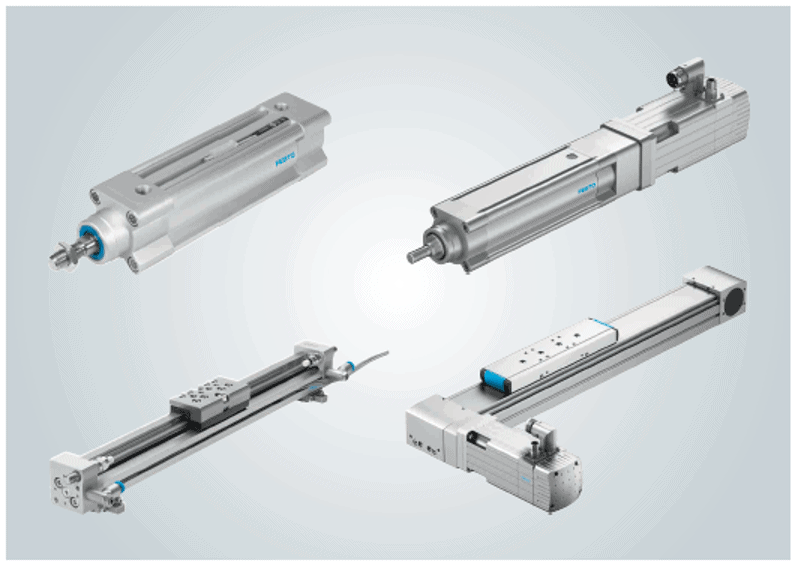

Typical axis technologies for electric drives

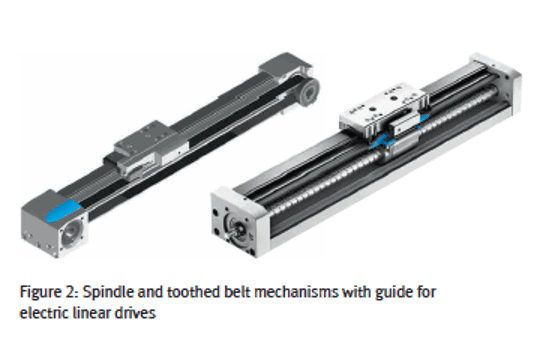

Electric actuators come in many different versions. As a rule, the motor’s rotary motion is converted into a linear motion by a mechanical system.

There are also electric direct drives (linear motors) that can generate a linear motion without any additional mechanical system. In practice, spindle and toothed belt drives are the most widely used linear drives.

Pneumatics: mechanical system and drive in one

Pneumatic drives have no such separation between the mechanical system and drive. The mechanical system of a pneumatic cylinder also executes the drive function. This means that pneumatic drives need much less space, making them very suitable for applications where space plays a central role.

Two or more positions?

Many industrial applications require cyclical travel between two defined points. This is a typical case for using pneumatic drives because of their ability to carry out a simple point-to-point motion with little effort.

If more than 2 (or 3) positions are to be approached, electric drive systems are often used. These systems can approach an almost unlimited number of intermediate positions and can thus also realise more complex motion sequences.

Dynamic response, force or both?

Depending on their design, electric drives can generate both high dynamic responses and high forces. They even outperform their pneumatic counterparts under extreme conditions. This is due to the different mechanical gear ratios; however, this does result in a direct correlation between dynamic response and force. What this means is that high forces, for example, can only be realised at the cost of the dynamic response (and vice versa). Spindle drives, for example, are particularly suitable for high forces at low to medium speeds, while toothed belt drives offer high dynamic response at the cost of maximum force.

When looking at dynamic response and force separately, the performance values of pneumatic drives are not as high as that of electric drives. Their ratio of force to dynamic response, though, is outstanding in many applications and superior to that of electric drives, especially in relation to installation space. That is why pneumatics is very well suited to applications requiring high performance density.

Continuous forces are the domain of pneumatics

Basically, linear motion processes can be divided into two phases: the motion itself and the holding phase at the end of the stroke. The importance of a component within the overall task can also be an indication as to which drive technology would be the most suitable. While pure motion tasks are executed very efficiently by electric drives, the technical operating principle of pneumatic drives makes them perfect for applying continuous forces and maintaining them for any length of time. This makes pneumatics the first choice for high continuous forces or long holding times.

Good control characteristics give the edge to electrics

Electric drives are normally used if an application requires free positioning or special acceleration sequences and speeds. Thanks to their good control characteristics, they can be flexibly adapted to a wide range of requirements. And unlike standard pneumatics, they can also approach an unlimited number of intermediate positions.

Servopneumatics is an interesting alternative if compressed air is to be used for a specific purpose, for example EMC or explosion protection. By having a displacement encoder, a proportional valve and a position controller, servopneumatics, as opposed to standard pneumatics, is a controlled system with which free positioning and detailed motion profiles can be achieved.

Load stiffness or flexibility?

In addition to special motion profiles, an application may also need high load stiffness or a deliberately flexible system. Since electric positioning drives are generally operated in closed-loop mode, they respond immediately to deviations in the required behaviour and make the necessary adjustments. Despite additional external loads, electric drives therefore generally follow their specified trajectory.

Pneumatic drives, on the other hand, can respond flexibly to external influences, even with high continuous forces, and can usually handle even overloading without any damaging effects. This characteristic can also be exploited to absorb shock or impact loads that would impair other drive types beyond repair in the long term.

Electric systems require specialised staff

One of the main differences between pneumatic and electric drive technology is the actual system setup and the associated complexity. Pneumatic systems have a simple setup and are impressively easy to install, commission, operate and maintain.

While electric systems have been state-of-the-art for decades, they are unquestionably more complicated to commission and require specialised staff with a higher level of technical knowledge. This is not only an important consideration for the plant manufacturer, but also for the customer who will have to operate and maintain the plant.

Economic comparison

Last but not least, the economic efficiency of a solution is also of great importance. An analysis of the procurement costs reveals that pneumatic solutions generally require much less investment than electric solutions. In addition, pneumatic systems are, as mentioned previously, quick and easy to set up and commission.

However, the operating costs must also be taken into account alongside the procurement costs. The energy costs in particular often constitute a key part of a system’s TCO (total cost of ownership).

Electric drives are an energy-efficient option, especially for tasks involving just motion. Their energy consumption is also loaddependent.

Compressed air, on the other hand, is often perceived as being a relatively expensive form of energy. But very few

customers know the (absolute) energy consumption of their pneumatic actuators. This means they do not have the criteria they need to decide whether an alternative solution could be more economical. Another challenge is ensuring that pneumatic systems are correctly used and sized, as these factors are also key to their efficient use.

The EnEffAH research project completed in 2012 (“Energy Efficiency in Production in the Drive and Handling Technology Field”, a joint project as part of the German Federal Government’s 5th and 6th energy research programme) provides a simple guide to the efficiency of an electric or pneumatic drive system. It clearly shows that electric drives are very efficient when it comes to large strokes with short holding times, and pneumatics is the preferred option for short strokes combined with holding tasks.

The question about which technology is more economical therefore depends on the application. However, basic trends about the efficiency of drives are often also applicable to their economic efficiency. Only a detailed investigation that considers the specific operating conditions can provide a clear and reliable answer to the question as to which technology is best.

Conclusion: it depends on the application!

The decision for or against a technology is based on several criteria, only some of which are examined here. Given the clear differences between pneumatics and electrics, it is not possible to make general statements about which technology is best. It is therefore important to focus on the problem and the associated parameters before choosing the most suitable solution. That is the only way to find the best technical and most economical solution.

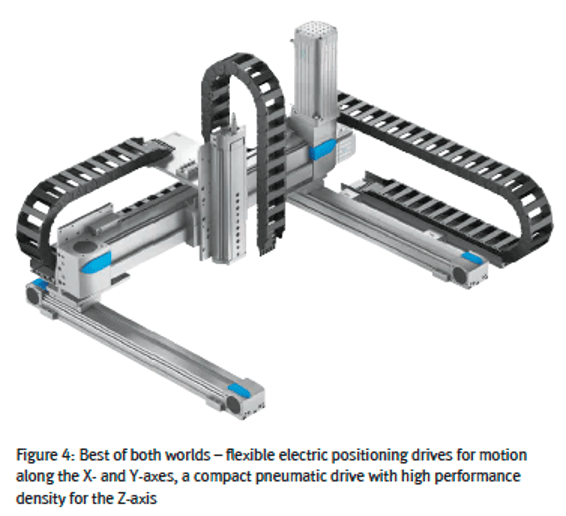

An appropriate combination of both technologies is, in many cases, the best solution. Three-dimensional gantries are an example. While motion along the X- and Y-axes requires flexible positioning and is ideal for electric drives, the Z-axes provide an opportunity for pneumatics to demonstrate its strengths such as low weight, high performance density and compact design. What we are dealing with is therefore not an “either/or” situation, but rather “best of both worlds”!

Which technology is suitable for which application?

A quick overview

Both pneumatic and electric drive technologies have their strengths and weaknesses. You need to weigh up the technical and economic criteria, and find the appropriate solution based on the application. The following table provides a quick overview of the most important characteristics:

Sources:

- EnEffAH research project; www.eneffah.de

(date of retrieval: 14.07.2016)

- Photos: Festo AG & Co. KG